Introduction Can an electric jackhammer truly break rocks? Many people wonder if these tools can handle tough materials like rocks effectively.In this article, we’ll explore the power and limitations of the electric jackhammer, specifically the corded demolition hammer.

Introduction When it comes to breaking concrete, one of the most common questions is: How thick of concrete can a jackhammer break? Concrete is one of the strongest materials in construction, but with the right tools, it can be broken into manageable pieces.

Introduction When using a jackhammer to break concrete, a common question arises: should you wet the concrete first? Whether you’re tackling a DIY project or a large demolition, this question can make a difference. Wetting concrete offers benefits, but also introduces safety risks.

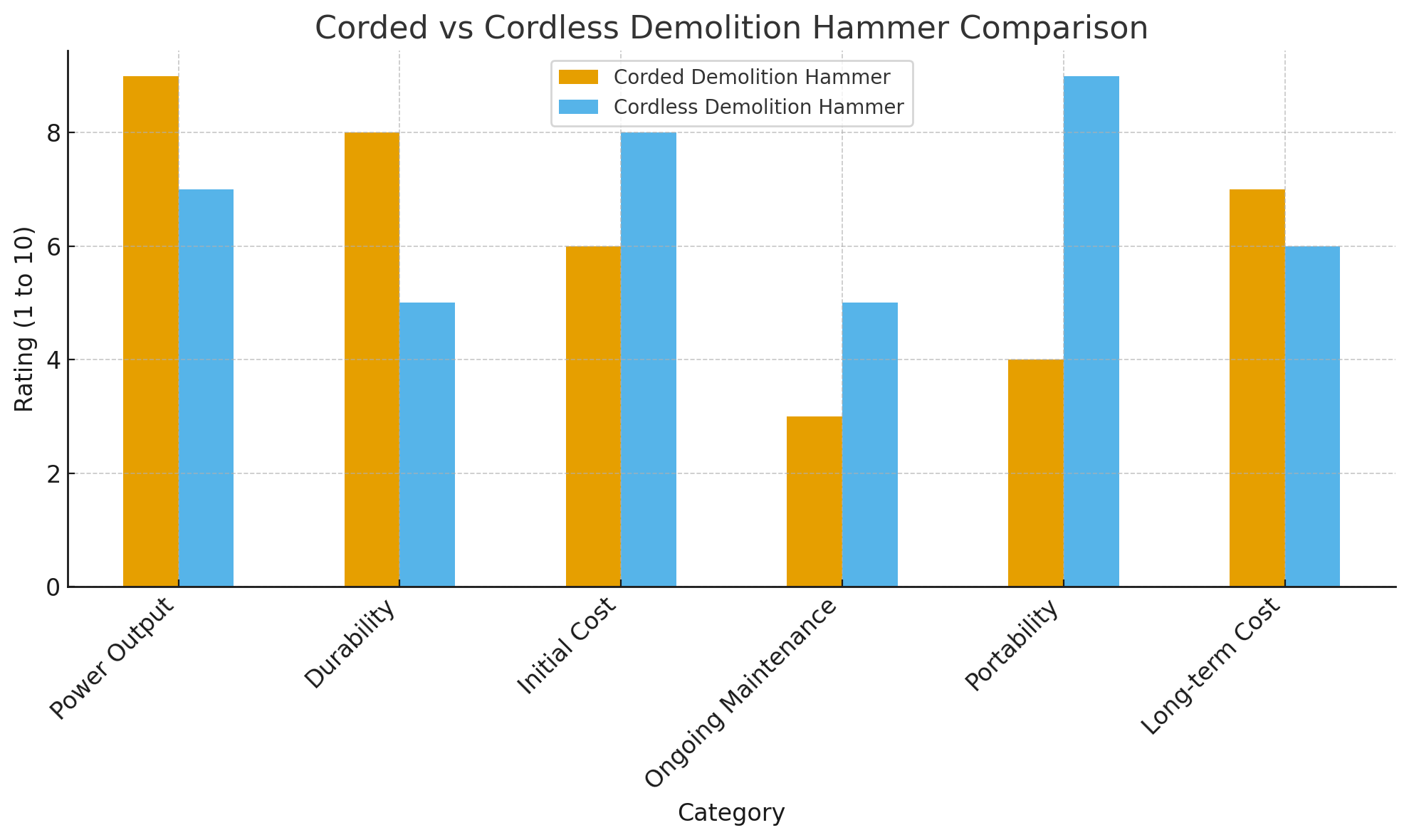

Introduction When it comes to breaking concrete, one of the most important decisions you'll make is whether to use a corded demolition hammer or a cordless demolition hammer. Each type has distinct advantages depending on your project's needs. The choice often comes down to power, portability, cost, and durability.

Introduction When tackling tough demolition jobs, a corded jackhammer (also known as a corded demolition hammer) can be your best friend. But how do you use it safely and effectively?

Understanding Cordless Power DrillsEver struggled with drilling tasks? Cordless power drills are crucial in DIY and professional settings. Yet, rookie mistakes can hinder efficiency. In this post, you'll learn how to avoid common errors and maximize your tool's potential.

Cordless Power Drills vs. Impact Drills: Key Differences ExplainedHave you ever wondered why some drills seem to make tasks effortless while others struggle? Cordless power drills are essential for various projects, but not all drills are created equal.

Ever wondered if an impact drill can double as a regular drill? This question puzzles many DIY enthusiasts and professionals alike. Impact drills and cordless power drills are essential tools, each with unique functions. In this post,

Ever wondered why cordless power drills have become game-changers in the DIY world? The secret lies in "brushless" technology. Understanding what "brushless" means on a drill is crucial for making informed tool choices. In this post, you'll learn how brushless technology enhances efficiency, power,

18V vs 20V Cordless Power Drills: Which Is Better?Ever wondered if the voltage of your cordless power drill really matters? Whether you're a DIY enthusiast or a professional, choosing the right drill can make all the difference. In this post,

When tackling heavy-duty renovation or construction tasks, from breaking through reinforced concrete to removing stubborn ceramic tiles, a demolition hammer becomes an indispensable tool. Unlike a regular hammer drill, which is designed for drilling holes, a demolition hammer is built solely for impact force, making it the professional’s choice for demolition jobs.

When investing in construction tools, one of the most common questions is: how long do demolition hammers last? For professionals and DIY enthusiasts alike, the durability of tools is crucial for saving time, money, and effort. Among the many options available, the corded demolition hammer stands out as one of the most reliable choices for heavy-duty work.

When planning a renovation or remodeling project, many people ask: Can I use a demolition hammer indoors? The short answer is yes—you can use a demolition hammer indoors, provided that you follow proper safety measures, prepare the work area thoroughly, and select the right type of hammer for your task.

Concrete is one of the most durable and widely used materials in construction. Whether in foundations, walls, or flooring, it provides structural integrity and long-lasting performance. However, when it comes to renovation, remodeling, or repair projects, there is often a need to break through concrete surfaces.

In construction and renovation projects, selecting the right demolition tool is crucial for efficiency, safety, and achieving precise results. Among the most widely used tools are the jackhammer and the demolition hammer.

When it comes to construction, renovation, or heavy DIY projects, selecting the right tool can make all the difference between a successful project and a frustrating experience.

In modern construction, tools are the backbone of productivity, precision, and safety. From drilling into concrete to cutting steel or shaping wood, the efficiency of every project depends heavily on the reliability of the equipment in use. For decades, corded power tools dominated job sites, offering consistent performance but with one major limitation—mobility.

In recent years, Cordless Power Tools have become an essential part of modern construction and industrial projects. Their portability, efficiency, and versatility allow workers to operate in challenging environments without being limited by power outlets, making them increasingly popular on job sites worldwide.

Carpentry has come a long way from its roots in manual hand tools, evolving into a trade that increasingly relies on power-assisted equipment. Traditional saws, chisels, and drills once required significant physical effort and time, but modern projects demand higher efficiency, precision, and flexibility.

Battery technology has become one of the most important factors driving the evolution of Cordless Power Tools. From their early days as limited, short-lived alternatives to corded equipment, cordless tools have now become essential for professionals across construction, carpentry, and industrial maintenance.

When it comes to breaking concrete, one of the most important decisions you'll make is whether to use a corded demolition hammer or a cordless demolition hammer. Each type has distinct advantages depending on your project's needs. The choice often comes down to power, portability, cost, and durability. In this article, we’ll compare both, focusing on their power, longevity, and long-term costs to help you choose the best tool for your job.

A corded demolition hammer delivers consistent, high-powered performance, making it the ideal choice for demanding tasks, especially when working with tough materials like reinforced concrete. It remains plugged into a power source, offering continuous power for extended work periods. On the other hand, a cordless jack hammer operates on battery power, which provides more flexibility but at the cost of power consistency. Cordless models are generally not as powerful, especially during long sessions, as their power can decrease as the battery drains.

Corded demolition hammers typically feature higher input power (ranging from 900W to over 1,500W), allowing for superior performance and faster work. These hammers are especially effective for breaking thick concrete. In contrast, cordless hammers—though improving in power—tend to be less efficient in high-demand situations. The typical cordless hammer may range from 500W to 1,200W, depending on the model, which means they struggle more with tougher concrete or prolonged use.

● Corded demolition hammer: Ideal for heavy-duty demolition tasks where consistent power is essential, such as large construction projects or frequent, continuous concrete breaking.

● Cordless demolition hammer: Best suited for lighter, intermittent work or jobs in areas where access to power outlets is limited, such as small DIY tasks or on-the-go demolition in remote locations.

Corded tools are designed for long-lasting performance due to their reliable connection to a constant power source. They don’t experience wear and tear from battery degradation, making them ideal for tough, long-term usage. These hammers can withstand extreme temperatures and prolonged work sessions, ensuring that they maintain performance throughout their life, especially when used in construction and demolition environments.

Cordless tools rely on batteries, which are subject to wear and gradual loss of charge capacity over time. While newer battery technologies like lithium-ion have improved the longevity of cordless hammers, the battery will eventually degrade, reducing overall performance. Frequent use of cordless hammers in demanding conditions can lead to faster battery wear, especially in high-demand tasks.

Corded tools typically require less maintenance than cordless tools. For a corded demolition hammer, the main maintenance concerns involve ensuring the power cord is in good condition and periodically checking internal components like motors and brushes. Cordless jack hammers require more attention, especially to the batteries. Regular charging habits, proper battery storage, and timely battery replacement are crucial for maintaining performance.

● Corded demolition hammer: Generally, corded models come at a lower initial cost. They don’t require batteries, chargers, or additional accessories, which makes them more affordable upfront.

● Cordless jack hammer: Cordless tools are typically more expensive, as they require the cost of batteries, chargers, and other accessories in addition to the tool itself. This can make the initial investment significantly higher.

● Corded models: The cost of maintaining corded tools is typically low. You may need to replace worn-out parts like the power cord or motor brushes, but this is infrequent.

● Cordless models: The main long-term cost of cordless tools comes from battery maintenance and replacement. Depending on usage, a battery may need to be replaced every couple of years, which can be costly.

● Corded demolition hammer: While you pay for electricity, the cost of operation is steady and predictable, with no need to worry about running out of power mid-task.

● Cordless jack hammer: In addition to the higher upfront cost, cordless hammers involve ongoing battery charging costs. The need for frequent recharging can also lead to downtime, depending on the project size.

Cordless demolition hammers shine when it comes to portability. They offer freedom of movement without being tethered to a power outlet, making them ideal for working in remote areas or tight spaces. You can take them anywhere, allowing you to tackle jobs where a corded tool would be impractical.

Corded tools are limited by their dependence on electrical outlets. While this can be managed with extension cords, it’s still less convenient than the unrestricted movement offered by cordless tools. However, the need for extension cords or power generators makes corded hammers less practical for outdoor or job site use.

The corded demolition hammer can present a safety risk due to the potential tripping hazard posed by cords, especially in cluttered workspaces. Cordless models, by contrast, eliminate this hazard. The absence of cords also reduces the risk of accidental power loss, as long as you have fully charged batteries available.

● For heavy-duty projects, where thick concrete or continuous breaking is required, a corded demolition hammer is typically the best choice due to its consistent power and endurance.

● For lighter tasks or projects that require portability, a cordless jack hammer is sufficient and offers more flexibility.

Consider the size of the workspace and the availability of power. For large, stationary jobs like roadwork or large building demolitions, a corded hammer is ideal. For on-the-go jobs, such as outdoor projects or work in tight, remote spaces, a cordless tool provides the mobility needed.

● DIYers may benefit more from the cordless demolition hammer due to its convenience and portability, especially for smaller, non-intensive projects.

● Professionals working on larger, heavy-duty projects should opt for corded models to ensure consistent power, durability, and lower long-term costs.

Both corded and cordless demolition hammers offer unique advantages. A corded model excels in power and efficiency for demanding tasks. However, a cordless jack hammer provides excellent mobility for lighter jobs or areas without power. For DIYers, a cordless tool offers great convenience, while professionals should choose corded hammers for long-term durability and efficiency. Mingpu offers high-quality, reliable demolition tools that provide exceptional value, catering to both casual and industrial users.

A: A corded demolition hammer provides continuous power, making it ideal for heavy-duty tasks. A cordless jack hammer offers greater mobility but has limited runtime due to battery constraints.

A: A corded demolition hammer typically delivers more consistent and higher power output, ideal for demanding concrete demolition, while a cordless jack hammer may have lower power efficiency due to battery limitations.

A: Cordless jack hammers are more suited for lighter tasks. For heavy-duty jobs, a corded demolition hammer is recommended as it provides sustained power.

A: A corded demolition hammer tends to last longer due to fewer parts that wear down over time, while a cordless jack hammer's battery may degrade, affecting its overall lifespan.

A: Corded demolition hammers are typically cheaper upfront, while cordless models require additional investments in batteries and chargers, increasing long-term costs.