Introduction Can an electric jackhammer truly break rocks? Many people wonder if these tools can handle tough materials like rocks effectively.In this article, we’ll explore the power and limitations of the electric jackhammer, specifically the corded demolition hammer.

Introduction When it comes to breaking concrete, one of the most common questions is: How thick of concrete can a jackhammer break? Concrete is one of the strongest materials in construction, but with the right tools, it can be broken into manageable pieces.

Introduction When using a jackhammer to break concrete, a common question arises: should you wet the concrete first? Whether you’re tackling a DIY project or a large demolition, this question can make a difference. Wetting concrete offers benefits, but also introduces safety risks.

Introduction When it comes to breaking concrete, one of the most important decisions you'll make is whether to use a corded demolition hammer or a cordless demolition hammer. Each type has distinct advantages depending on your project's needs. The choice often comes down to power, portability, cost, and durability.

Introduction When tackling tough demolition jobs, a corded jackhammer (also known as a corded demolition hammer) can be your best friend. But how do you use it safely and effectively?

Understanding Cordless Power DrillsEver struggled with drilling tasks? Cordless power drills are crucial in DIY and professional settings. Yet, rookie mistakes can hinder efficiency. In this post, you'll learn how to avoid common errors and maximize your tool's potential.

Cordless Power Drills vs. Impact Drills: Key Differences ExplainedHave you ever wondered why some drills seem to make tasks effortless while others struggle? Cordless power drills are essential for various projects, but not all drills are created equal.

Ever wondered if an impact drill can double as a regular drill? This question puzzles many DIY enthusiasts and professionals alike. Impact drills and cordless power drills are essential tools, each with unique functions. In this post,

Ever wondered why cordless power drills have become game-changers in the DIY world? The secret lies in "brushless" technology. Understanding what "brushless" means on a drill is crucial for making informed tool choices. In this post, you'll learn how brushless technology enhances efficiency, power,

18V vs 20V Cordless Power Drills: Which Is Better?Ever wondered if the voltage of your cordless power drill really matters? Whether you're a DIY enthusiast or a professional, choosing the right drill can make all the difference. In this post,

When tackling heavy-duty renovation or construction tasks, from breaking through reinforced concrete to removing stubborn ceramic tiles, a demolition hammer becomes an indispensable tool. Unlike a regular hammer drill, which is designed for drilling holes, a demolition hammer is built solely for impact force, making it the professional’s choice for demolition jobs.

When investing in construction tools, one of the most common questions is: how long do demolition hammers last? For professionals and DIY enthusiasts alike, the durability of tools is crucial for saving time, money, and effort. Among the many options available, the corded demolition hammer stands out as one of the most reliable choices for heavy-duty work.

When planning a renovation or remodeling project, many people ask: Can I use a demolition hammer indoors? The short answer is yes—you can use a demolition hammer indoors, provided that you follow proper safety measures, prepare the work area thoroughly, and select the right type of hammer for your task.

Concrete is one of the most durable and widely used materials in construction. Whether in foundations, walls, or flooring, it provides structural integrity and long-lasting performance. However, when it comes to renovation, remodeling, or repair projects, there is often a need to break through concrete surfaces.

In construction and renovation projects, selecting the right demolition tool is crucial for efficiency, safety, and achieving precise results. Among the most widely used tools are the jackhammer and the demolition hammer.

When it comes to construction, renovation, or heavy DIY projects, selecting the right tool can make all the difference between a successful project and a frustrating experience.

In modern construction, tools are the backbone of productivity, precision, and safety. From drilling into concrete to cutting steel or shaping wood, the efficiency of every project depends heavily on the reliability of the equipment in use. For decades, corded power tools dominated job sites, offering consistent performance but with one major limitation—mobility.

In recent years, Cordless Power Tools have become an essential part of modern construction and industrial projects. Their portability, efficiency, and versatility allow workers to operate in challenging environments without being limited by power outlets, making them increasingly popular on job sites worldwide.

Carpentry has come a long way from its roots in manual hand tools, evolving into a trade that increasingly relies on power-assisted equipment. Traditional saws, chisels, and drills once required significant physical effort and time, but modern projects demand higher efficiency, precision, and flexibility.

Battery technology has become one of the most important factors driving the evolution of Cordless Power Tools. From their early days as limited, short-lived alternatives to corded equipment, cordless tools have now become essential for professionals across construction, carpentry, and industrial maintenance.

Can an electric jackhammer truly break rocks? Many people wonder if these tools can handle tough materials like rocks effectively.

In this article, we’ll explore the power and limitations of the electric jackhammer, specifically the corded demolition hammer. We’ll help you decide if it's the right choice for your rock-breaking tasks.

An electric jackhammer is a tool that combines a motor-driven hammer mechanism with a heavy-duty chisel or bit to break through hard surfaces. It operates by converting electrical energy into mechanical impact, driving the bit into the material with powerful force. Electric models are commonly used for small to medium-sized demolition tasks, as they are easier to handle and more convenient than pneumatic or hydraulic options.

The most common types of electric jackhammers are corded, meaning they require a constant power source, typically from an electrical outlet or generator. These machines are generally lightweight, making them ideal for tasks where mobility and convenience are important.

● Corded Demolition Hammer: These jackhammers are plugged directly into an electrical outlet or generator. They are more powerful than their cordless counterparts, with consistent power supply that makes them ideal for long-duration tasks like breaking rocks.

● Cordless Electric Jackhammers: Though more convenient for mobility, cordless models often lack the raw power required for heavier tasks like rock demolition. They are typically used for lighter materials or in situations where being tethered to a power source isn’t feasible.

Electric jackhammers can break rocks, but their effectiveness depends on the type of rock and the model of the jackhammer. Rocks like limestone, sandstone, and some types of granite can generally be broken with a well-powered electric jackhammer. However, harder materials like dense granite or boulders may require a more powerful pneumatic or hydraulic model.

For general DIY projects or smaller commercial tasks, an electric jackhammer will likely be sufficient for rock breaking, particularly if the rock is not extremely tough. However, for larger or more stubborn rocks, it might struggle to produce the necessary impact force to break through effectively.

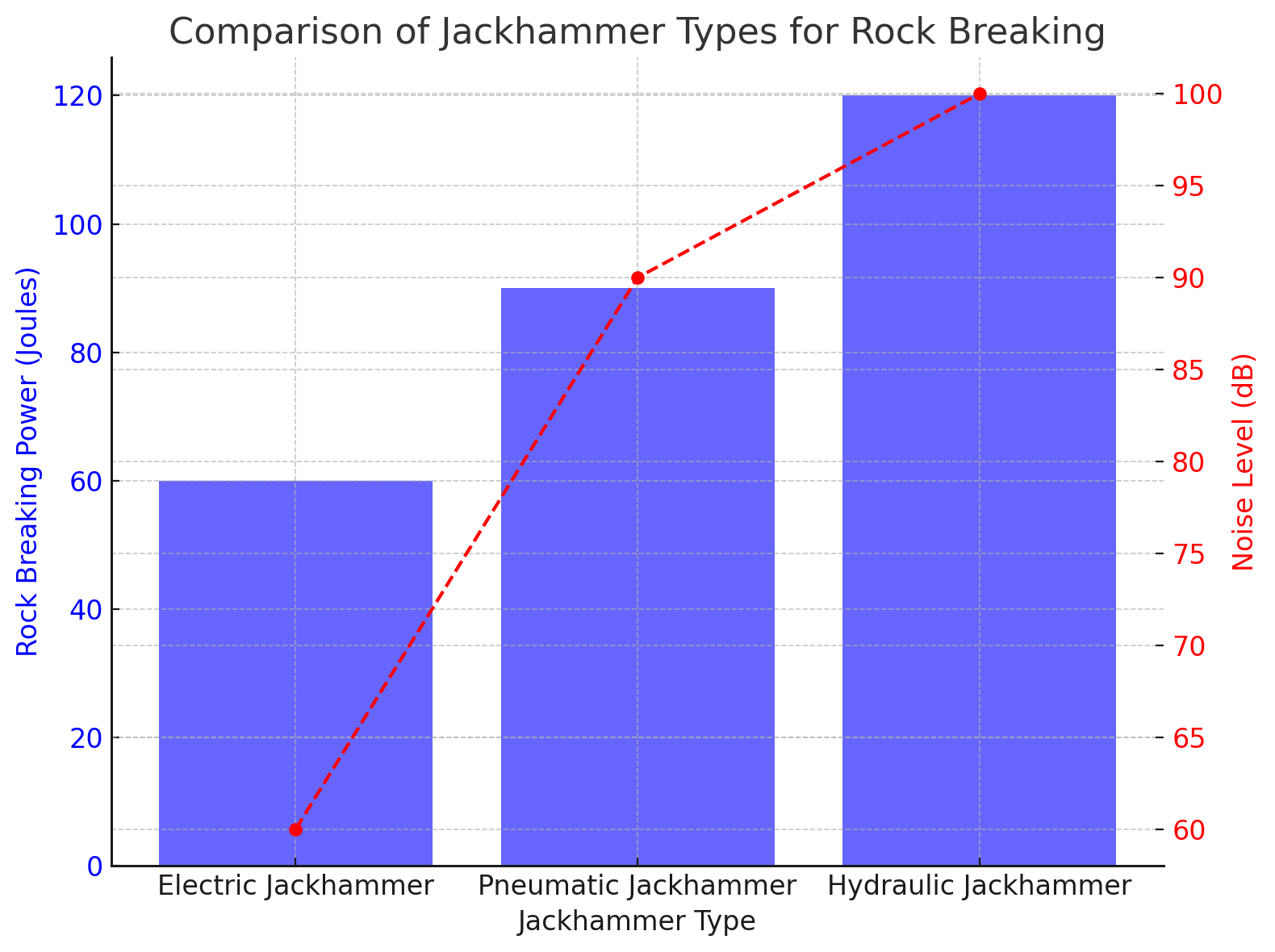

● Corded Demolition Hammer vs. Pneumatic vs. Hydraulic Jackhammers: Pneumatic and hydraulic models are known for their superior power. While pneumatic models are fueled by air compressors and hydraulic models use fluid power, these systems can generate far more impact energy than electric models. Therefore, they are typically used for larger, more demanding projects, such as breaking large boulders or heavy concrete slabs.

● When to Use a More Powerful Jackhammer: If you are working with extremely dense or thick rock, such as large granite boulders, an electric jackhammer may not provide enough force. In these cases, it’s advisable to opt for a pneumatic or hydraulic model to achieve better results more quickly.

The size and weight of an electric jackhammer play a crucial role in its ability to break tougher materials like rocks. Larger, heavier models tend to generate more impact force, making them more efficient at breaking through hard surfaces. A lightweight jackhammer might struggle with larger rocks, especially if they are compact or very dense.

The right attachment is key to effective rock breaking. Electric jackhammers come with various chisel bits, each designed for specific tasks. For rock breaking, pointed chisel bits or heavy-duty breaker bits are ideal. These bits focus the impact energy on a smaller area, allowing for deeper penetration into the rock.

Choosing the correct bit will directly affect the success of your rock-breaking project. Using a flat or wide chisel, for example, might be more suitable for asphalt but less effective on harder rocks.

Impact force is one of the most critical factors in determining whether an electric jackhammer can break rocks effectively. Electric models typically offer impact forces that range from 20 to 50 joules, while pneumatic or hydraulic models can deliver much higher forces. The power of a corded demolition hammer is usually sufficient for smaller tasks, but it may fall short when tackling larger or tougher rocks.

Electric jackhammers are generally lighter and more portable than their pneumatic or hydraulic counterparts. This makes them ideal for DIY projects or smaller-scale tasks like breaking garden rocks, sidewalk repairs, or demolition of light concrete. The ability to plug into a standard outlet means you don’t need to worry about additional power sources like air compressors or hydraulic pumps.

One of the most significant advantages of electric jackhammers over pneumatic ones is noise control. Pneumatic models tend to be much louder, requiring ear protection to prevent hearing damage. Electric jackhammers, on the other hand, are quieter and more suitable for residential areas or indoor projects where noise can be a concern. Additionally, electric models often have vibration reduction features that help reduce user fatigue.

Electric jackhammers are designed with ease of use in mind. Their lighter weight and simpler operation make them a great choice for homeowners or small contractors who need to tackle rock breaking without the complexity or expense of more powerful models. With proper training and safety precautions, non-professionals can efficiently use an electric jackhammer for a variety of tasks.

Despite their advantages, electric jackhammers are limited by their power. While they can handle smaller rocks or medium-density materials like limestone, they may struggle with larger, more solid rocks. For very tough, dense rock like granite or boulders, you’ll likely need to consider pneumatic or hydraulic models that can generate more force and penetrate deeper.

Another limitation of electric jackhammers is their reliance on a constant power source. Corded models require you to stay close to an electrical outlet or a generator, which can limit mobility. In remote locations or when working on large areas, this could become a significant inconvenience. If you are working on a site where power is not readily available, a cordless or gas-powered model may be more suitable.

Electric jackhammers are most effective for small to medium-scale rock-breaking tasks. They are great for breaking rocks in gardens, small landscaping projects, or clearing smaller debris. For example, breaking smaller rocks or removing soft to medium-density rocks such as limestone or sandstone is well within the capabilities of an electric jackhammer.

For larger rock removal projects, such as breaking massive granite boulders or demolition at a commercial site, a more powerful tool is required. In these cases, pneumatic or hydraulic jackhammers are better suited due to their higher impact force. These models are often used by professionals in construction, mining, and quarry work.

Electric jackhammers are also a great choice for indoor work or residential projects. Their quieter operation and reduced vibration make them ideal for use in areas where noise and disruption need to be minimized. They are often used for tasks like breaking up concrete floors or removing rocks in confined spaces.

Before starting any rock-breaking task with an electric jackhammer, it’s essential to wear appropriate personal protective equipment (PPE). This includes:

● Gloves to protect your hands from flying debris.

● Hearing protection to shield against the loud noise produced by the jackhammer.

● Safety glasses to protect your eyes from debris.

Additionally, ensure that your posture is correct to reduce strain. Stand with your feet shoulder-width apart and keep the jackhammer slightly tilted toward you for better control.

When using an electric jackhammer for rock breaking, always let the tool do the work. Avoid putting excessive pressure on the jackhammer, as this can reduce its effectiveness and cause it to slip. Start with light pressure and let the impact force gradually break through the rock. If working on a larger area, break the rock in sections rather than attempting to tackle it all at once.

Electric jackhammers are a practical choice for breaking small to medium-sized rocks and softer materials like limestone. Though they don't match the power of pneumatic or hydraulic models, their portability, ease of use, and quieter operation make them ideal for DIYers and residential projects. When selecting the right jackhammer, consider the rock type, project size, and power access. For larger projects, pneumatic or hydraulic models may be more suitable. Mingpu offers high-quality tools that deliver value with reliable performance and innovative features, making them an excellent choice for both DIYers and professionals.

A: Yes, a corded demolition hammer can break smaller to medium-sized rocks. While it may not have the same power as pneumatic models, it's still effective for DIY projects and residential tasks.

A: A jack hammer, especially electric models, is ideal for breaking softer rocks like limestone and sandstone. For harder rocks, pneumatic or hydraulic models may be required for better results.

A: A jack hammer is lighter and quieter than pneumatic or hydraulic hammers. While it works well for medium-sized rocks, heavier-duty models provide more power for tougher materials.

A: While an electric jackhammer can handle smaller rocks, large or dense rocks may require a more powerful pneumatic or hydraulic jackhammer to break effectively.

A: Yes, a corded demolition hammer is a great option for DIYers working on smaller rock-breaking projects. It's portable, easy to use, and quieter compared to air-powered models.